@irukard you wrote that you know how to building semi professional Stevenson cage quite cheap. Could you please share your design with us?

Yes! I was planning to aggregate all information and place it on github. With some instructions, 3D models and links.

The hardest part of building Stevenson Screen is the screen part itself. So check this out:

Classen - the Polish company specialized in doors has in it’s offer furniture fronts made of solid pine.

They are single slope only. In theory they are not as good as two slope screens, but in my opinion they are good enough for Citizen Science applications. I couldn’t find any difference in performance.

Basically for small Stevenson screen for your sensor you can use following parts:

- Two 394x395mm - as front and back (retail price 23,48 PLN ≈ 5€)

- Two 294x395mm - as sides (retail price 19,98 PLN ≈ 4.3€)

So screens will cost you less than 20€.

You need add some structural elements, double roof, etc. But it can be easily manufactured from Baltic Birch plywood. Of course all elements needs to be impregnated and painted white with glosy oil-alkyd enamel.

Interesting idea to use furniture fronts.

Thanks!

Thanks!

In Germany some CLASSEN furniture front parts are available at Hornbach hardware stores (named Lamellentür offen):

https://www.hornbach.de/shop/Moebelbau/Lamellentueren-Profiltueren/S9455/artikelliste.html

But not in the small dimension (height) that you referenced.

From your experience, would it be possible to cut such a type of door with larger height in pieces of suitable height? Are the slats glued to the frame?

That may be hard. As far as I know the slats are not glued, they are fitted into milled holes between frames.

I would say it’s a nice idea. Especially roof made from polycarbonate panel. But orientation or holes in roof is wrong in my opinion. They should go along the slope of roof not perpendicular. That would allow better air circulation inside roof and lower amount of thermal energy from sun transferred inside the cage. This might be a good solution to introduce in next generation of Sensor.Community sensors.

Actually, nice idea! Plastic ventilation squares are widely available and cheap. Though they might not be protected from UV.

Also there are various ready made shields on Ali:

https://www.aliexpress.com/wholesale?catId=0&initiative_id=SB_20210318023924&origin=y&SearchText=shield+for+thermo+sensor

It would be interesting to test various designs and to choose the best of them.

And how do you plan to source them from China in huge quantities? I don’t like CO2 footprint of this idea. I would rather like to use something produced locally in Europe. Preferable from recycled materials.

Hi, I wanted to try this design, but unfortunately never got myself to print it yet: Luftdaten Stevensson screen by Naesstrom - Thingiverse

I am not planning anything ![]() Just give the link to product which can be potentially compared with another products. The idea is to select the best possible solution!

Just give the link to product which can be potentially compared with another products. The idea is to select the best possible solution!

Of course environmental impact is important in the comparison!

Unfortunately 3D print doesn’t scale up (unless you are Joseph Prusa). I got in mind that somewhere in near future we need to be prepared for sending hundreds of kits in very short time. And every design decision I make must be confronted with that. Sensor.Community project is far behind “let’s prototype something” phase. We need to prepare cost-efficient and scalable solutions which can be quickly deployed. With good Open Hardware documentation, instruction manuals, etc.

So basically every part we use should be easily available with many potential replacement options on local market. We also need to address environmental impact of our design. No waste, reuse of existing designs and technology.

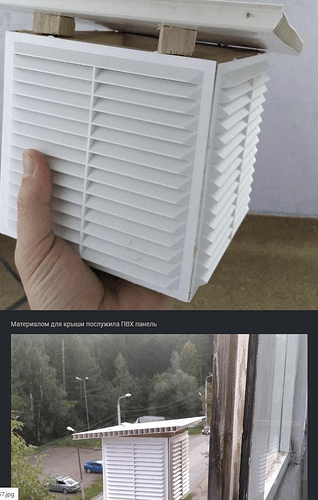

I would love to enclose sensor inside enclosure like this:

But unfortunately they are not cheap with price around 40-50€. But having ready to use enclosure saves a lot of time.

Solution with ventilation covers seems to fit our needs but requires more work. It would cost around 15-20€.

Kit with ready to assemble wooden cage with Stevenson screens made from furniture doors would be around 70-100€. Cost would include preparing and painting all wooden parts, hinges, lock, screws, etc.

In contrast to commercially available Stevenson Screens - 100€ or even 200€ is a fraction of price.

I think we should explore all three (or four) options. Build them, evaluate results and share the knowledge with the Community.

I think wood is not good material for outdoor…

Some uv-resistant plastic plates I think may be found for DIY.

Producing in Europe is very expensive.

AFAIK all professional Stevenson screens used in meteorology are made from wood. Polish (European?) norms for such construction points out pine as build material. They also specify impregnation methods and type of paint. Wood is also biodegradable.

Production in Europe is expensive relative to China because we do not add environmental costs. If I have a choice between local production in Europe and China, I will always pick the Europe. We all need to understand that optimizing our carbon footprint comes with a cost. And sooner or later we had to pay for that. Let’s be a part of solution, not part of problem.

Just a thought. This looks like it can be created with disposable bowls/plates on top of eachother and then the bowls of https://www.ecoayez.com/ might be an option. Cut out the bottom of a bowl, except for the top one and put it together. I have no experience with the product though.

Interesting idea! The only problem is that the wooden plates might degrade too fast as they are specifically made biodegradable. But, maybe with the use of protective materials (paint) the biodegradation process can be extended?

I’ve ordered bowls and will update you when I have some more info. I’m curious if it’s a workable idea.

The bowls are received and I played around with it.

The bowls are still waterproof after being submerged in water for 3 days. They do absorp some water and loose a bit of shape but not very much. They are very light and easy to work with, though the lightness needs to be taken into account because if it’s not fixed properly, the wind will blow it away. I used a scissor to cut the hole out of the bowls. It’s not very accurate but the bowls are not damaged. I placed 6 bowls together and hit 4 holes into it with a nail to hold it together with bamboo skewers. It’s possible to drill the skewers into the wood but it requires strength and a few extra skewers. The bowls are not exactly the same shape so the spacing between the bowls is a bit tricky. At this moment I placed some paper in the middle part where the equipment should go, just to check if’s protected. This is the result so far and I think it can work.